News Center

Manufacturing productivity has undergone three profound changes, the first centered on water and steam power, also known as the Industry 1.0 era. The second Industrial Revolution was the age of electricity, with the advent of the generator and a leap in productivity. The third is the computer age, the breakthrough of electronic computer technology has promoted the development of production automation. Today, we are ushering in the fourth industrial revolution, the era of Industry 4.0 with information technology as the core.

Industry 4.0 or Industrial Internet of Things refers to connecting all production elements such as all equipment, computers, people and products, and collecting rich big data from them, and then guiding production through data analysis, and finally making the production line reach the highest efficiency. In fact, Industry 4.0 is to improve the flexibility and efficiency of factories through information technology to help enterprises provide competitiveness.

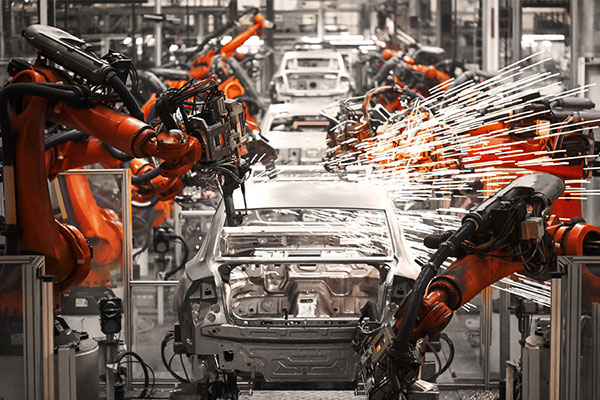

So, in the era of Industry 4.0, how will the robot industry change? In recent years, robots have developed into a major role in the manufacturing industry, and machine replacement has alleviated the pressure of factory recruitment, improved the production efficiency of the factory, and played an indispensable role in modern manufacturing. When industrial robots encounter Industry 4.0, there will be subtle changes, and some robot manufacturers have begun to use the Industrial Internet of Things to achieve online monitoring, predictive maintenance, process optimization, etc., to elevate the ability level of robots to a higher level.

Zero downtime

In the rush of the production line, the machine is running constantly, and the factory is creating value every second. Production managers do not want the machine to stop, but machine wear and failure are difficult to avoid, and the ideal 24-hour non-stop operation is difficult to achieve. However, the technology of Industry 4.0 provides new ideas, through the industrial Internet of Things connection and monitoring, can further ensure the normal operation of the machine.

Robotics manufacturer Fanuc and General Motors have developed a cloud-based software platform, ZDT, which is a zero-downtime solution for analyzing data collected from robots in General Motors' factories. The scheme was originally designed to eliminate downtime, but as more and more data was collected, the ZDT system capacity grew and produced a huge return. Since the start of the project in 2014, GM has avoided more than 100 major unplanned shutdowns, which can easily cost millions of dollars per outage for an automotive plant.

The zero downtime solution enables production facilities to have predictive maintenance capabilities, where data captured from robots is then processed before a failure occurs, thereby avoiding unplanned downtime. As long as enough data is collected from the robot, it can diagnose itself based on small changes, and then adjust it to improve its overall efficiency. Through data analysis to understand the condition of the machine, the manager can arrange a reasonable maintenance plan, rather than unnecessary regular maintenance.

Autonomous robot

The significance of Industry 4.0 model is not only to prevent downtime, including industrial Internet of Things, information physical systems, cloud computing, robotics, big data, edge computing and other technologies, the integration of information technology (IT) and operational technology (OT), further improve the level of machinery, making factory equipment more flexible and intelligent.

In the future manufacturing industry, robots will be connected to servers, through the analysis of big data, to achieve more reasonable scheduling control. With the help of information technology, the work of robots can be more coordinated and intelligent than ever before, for example, mobile robots in factories can identify the surrounding environment, smoothly avoid obstacles, and effectively cooperate with other robots under the monitoring of the scheduling system.

The robot's autonomous decision-making comes from the surrounding environment analysis and more information support. It receives the work signal from the real-time production system and the manufacturing execution system, and then performs independent work according to the signal, such as the supply of raw materials on the production line. Only when the robot knows the production status of the production line can it judge when to send the material.

In addition, the robot can plan the best route through big data analysis to shorten the time of machine operation. The robot is connected to the cloud computing platform, and through rich data insight, it can maximize the equipment capacity and production efficiency, and ensure higher product quality.

(Source: Control Engineering Network)

Return to Overview